CALL US TOLL FREE | 9am-7pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

ABOUT

CALL US TOLL FREE | 9am-7pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

ABOUT

To view the lift inspection guide Click Here.

BendPak's HDS-Series 4-post lifts are engineered to meet the strenuous demands of even your toughest professional lifting jobs. In particular, this HDS-14 is the kind of sturdy beast you want as the backbone of your shop. Designed into every HDS-Series lift is a laundry list of key features as long as your arm to ensure that BendPak is the absolute best you can buy.

Our competitors might say we overdo it, but we don't include components for the sake of frills and flash. We design our lifts with the attributes we feel should come standard with every lift-the kind of lift we would want to (and do) own. You can always count on BendPak lifts for increased durability, safety and productivity. Spend less time worrying about what you're working under and more time doing what you love. Our commercial-grade lifts are second to none and recognized the world-over as benchmarks of dependability and quality.

The HDS-14, the extended length HDS-14X, and the Super-Tall HD-14TL four-post models provide a generous 14,000-lb. lifting capacity and feature extended runways to accommodate a wide variety of vehicle wheelbases.

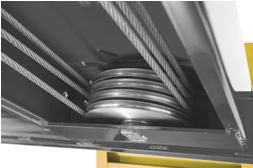

Dual-hub Cable Sheaves

Huge 10-1/2" diameter cable sheaves within the runway and cross tubes combined with massive 2-1/4" diameter sheave axles dramatically improve cable wear and critical component lifespan meaning you'll spend less money in service related expenses down the road. Dual-hub cable sheaves reduce stress, fatigue and wear.

Heavy-duty aircraft cable

BendPak's HDS-Series lifts feature four 1/2" diameter 6 x 25 stainless-steel lifting cables that have a breaking strength of over 14,000 pounds each. This aircraft-quality cable was specifically designed for lifting applications and provides a great balance between abrasion resistance and fatigue.

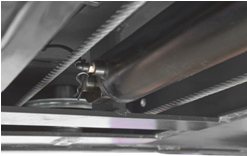

Built-in Lubrication

Grease fittings are located on every sheave and sheave axle to help keep these critical parts well lubricated and to simplify periodic maintenance.

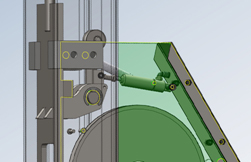

Hidden Hydraulic Cylinder

Each HDS-Series four-post is equipped with a single 3-1/2" diameter hydraulic cylinder hidden away under the runway for maximum performance and reliability and minimum exposure to elements. The welded cylinder body is made from high strength steel tubing produced to exceed ASTM specifications. The hydraulic cylinder features a one-piece, pilot fitted, machined steel piston wrapped with high-durometer, mechanically loaded rod seals, pressure loaded U-cup piston seals, backups and wear bands that virtually eliminate any fluid bypass. The micro-smooth chrome-rod is machined from high yield, ground and polished C-1045/50 micro-alloy steel and plated to a minimum of .001 1/2 diametrically, to ensure superior cylinder operation and life.. This combination of superb base material and superior processing ensures straight, smooth, cylinders that will provide years and years of dependable trouble-free service.

The hydraulic cylinder features a one-piece, pilot fitted, machined steel piston wrapped with high-durometer, mechanically loaded rod seals, pressure loaded U-cup piston seals, backups and wear bands that virtually eliminate any fluid bypass. The micro-smooth chrome-rod is machined from high yield, ground and polished C-1045/50 micro-alloy steel and plated to a minimum of .001 1/2 diametrically, to ensure superior cylinder operation and life.. This combination of superb base material and superior processing ensures straight, smooth, cylinders that will provide years and years of dependable trouble-free service.

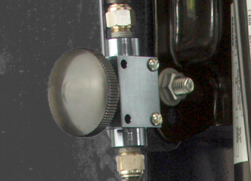

Flow Restrictor

An integrated hydraulic flow restrictor provides a controlled descent in the unlikely event of an unexpected hose rupture.

Durable Powder Coat

A durable powder coat finish can withstand harsh environments and chemicals usually inspected then sandblasted. (2) All parts are washed in five-stage phosphate tanks then immediately dried, to avoid rusting. (3) All surfaces and/or threaded holes that need to be masked or plugged are done so with high-temperature masking tape and silicone plugs. (4) The parts are given a quick thinner wipe to remove any light debris or fingerprints. (5) Finished parts are hung on an electro-statically grounded conveyor line, then powder is applied using an electrostatic spray gun. (6) Once the parts are powder coated, the carts are rolled into our curing oven and baked at 400 degrees for 15 for 45 minutes.

Large Base Plates

10" x 12" base plates provide a solid foundation for the HDS-14.

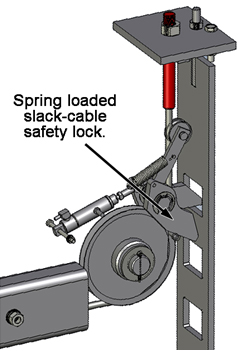

Spring-loaded Safety Locks

Spring-loaded safety locks automatically engage continuously during rise and adjustable safety ladders allow for precise runway leveling even when installed on sloped floors.

Push-button Pneumatic Lock Release

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders will provide years of trouble-free service.

Secondary Lock System

A secondary lock system is on constant guard and acts as a slack-cable device in the unlikely event of an unexpected cable failure.

Integrated Design

Lifting cables, airlines, safety latches and sheaves are all fully enclosed within lift structure.

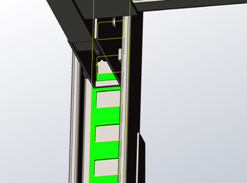

Adjustable Height Locking Positions

Each column features multiple adjustable height locking positions for variable-height parking and infinite leveling. 12" x 10" base plates provide a solid foundation.

Electric Hydraulic Power System

A maintenance-free electric hydraulic power system assures ultimate dependability. All operator controls are conveniently located within easy reach.

Non-skid Runways

Non-skid runways provides maximum grip, even when the runway surface is wet or oily. Extended length approach ramps feature automatic rear wheel chocks and help when loading low ground clearance vehicles.

Longer Approach Ramps

These approach ramps were designed a little longer to help when loading low ground clearance vehicles. It's the little bit that makes a big difference.

Flexible Protective Conduit

Hydraulic hoses and airlines are routed through a flexible protective conduit.

Optional Rolling Bridge Jack

Optional 7,000-pound capacity rolling jacks (model RJ-7) make a great addition to increase service capacity. RJ-7 bridge jacks are used to raise the front or rear portion of a vehicle off the runways allowing operators to perform efficient wheel and brake service. A pair of jacks allows the entire vehicle to elevated. Each jack has telescoping arms and frame contact pads that can be extended over the runways and positioned under vehicle lifting points. Telescoping rail supports accommodate adjustable runways for different tread widths. Each jack features three safety-lock positions and stackable truck and van adapters for increased lifting height and better access to frame contact points on high ground-clearance vehicles. The jacks come equipped with a commercial grade air-hydraulic pump requiring a maximum pressure of 125 PSI and 10-20 CFM.