CALL US TOLL FREE | 9am-7pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

ABOUT

CALL US TOLL FREE | 9am-7pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

ABOUT

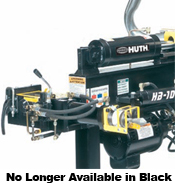

Includes 3" Bending Tooling & 3” Segment Expander

Huth has upgraded a number of electrical components to improve reliability. The control button box has been taken away from the "front" of the bender, and replaced by a rotary switch on the side of the frame. This also opens more space between the bending area and the operator. Some supporting components have been upgraded as well.

These changes improve the lifetime value of the Model 1600/HB-10. They are often in service for 25 years or more! This change reduces the total number of components required for the same amount of quality and function. If anything does eventually need replacing, they are easier, and less expensive overall, to replace.

This new control is the same one you will find on our new HB-05 model.

Huth's HB-10 Complete Bender Package includes Huth's newest Manual Knee Control Bender and comprehensive tooling package - everything you need to create O.E.- fit and custom-bent pipes.

The HB-10 is Huth's entry level bender, designed to introduce you to Huth quality while showing you the incredible profit potential that awaits you.

The HB-10 features knee control activation, manual depth-of-bend control and 58,000 lbs. of bending power - more than enough for 3" tubing.

Built-In Swager/Expander

The built-in heavy duty swager/expander gives you complete end-finishing capabilities - 1" to 3" tubing on the swager end and 1" to 51/2" tubing on the expander end.

With Huth’s Accu-Sizer™ automatic bull’s-eye expanding system, you’ll be able to dial in precise expansions every time.

Knee Control

Slim Knee Control Activation allows you to get closer to your work for quick, precise bending.

An Easy-to-Read Bend Indicator shows how far into a bend you are.

Plus, you receive bending dies, end-finishing tooling and a Huth DVD - everything you need to start bending pipes for thousands of applications.

Huth 3" Tube Bend (top on tube) vs. Asian-made

(Notice dimpling on bend in lower sample)

Huth 3" Tube Bend (tube to left) vs. Asian-made

(Notice tube flattening on the right)

The Easy to Use Pipe Bender

A compression pipe bender is an extremely powerful and versatile tool, but many who have not used one don’t fully appreciate how easy it is to use. When we get people to do their first bend, intimidation tends to fade away and enthusiasm to do more takes over!

There are two ends to the machine … the bending end, and the end-forming end. We’ll focus on the bending end to show just how simple this tool is. There are 3 things you need to know in advance … the distance between bends, the orientation of the desired bend, and the depth of the desired bend.

Plot your distances with a marker: Mark your pipe where you want your bends, working from left to right.

Now turn the bender on … you are almost ready to go: Apply lubrication and set your pipe in the jaws.

Setting a rotation dial to keep oriented: Prior to your 1st bend, setting a rotation dial on the far right end of your pipe, set to zero, will keep you oriented as your progress through multiple bends on each pipe. This is especially important if you are using bending program cards.

Choose Bend radius: Smaller radii give tighter bends, larger radii are more forgiving. Normally smaller tubes utilize smaller radii (larger tubes use larger radii) with a minimum 1.5-2X the tube OD.

Bend to the right depth: Every bender has a depth of bend indicator, and automatic benders let you pre-set the depth of bend. The pointer tells you when you reach your target bend angle.

Basically, that’s it. There are times when a bit more knowledge helps (When do I use a ½ shoe? What do I use for thin-walled material?). But these are compression bender basics for bending with your machine!

"Bending exhaust pipe without cards? Watch this!"